On June 16, after two days of serious on-site inspections and data review by 3 ASME renewal joint inspection team experts, at the final meeting of the ASME "U" stamp renewal joint inspection, the joint inspection team leader Shao Yong announced that our company has passed this ASME successfully. Joint inspection review for renewal. This is an affirmation of the company's quality control system and manufacturing capabilities, and it is also of great significance for our company to further develop the international market!

The ASME standard regulates the design, manufacture and inspection process of boilers and pressure vessels. To enter the international market, domestic pressure vessel manufacturers must obtain market access permits from corresponding countries or regions. The ASME Boiler and Pressure Vessel Code issued by the American Society of Mechanical Engineers, as an internationally recognized authoritative code, is widely recognized around the world and is used as a standard for boiler and pressure vessel design, manufacturing, inspection, and inspection. The ASME Boiler and Pressure Vessel Code is applicable to boiler and pressure vessel manufacturing and installation companies in the petroleum, chemical and electric power industries.

For the ASME "U" stamp renewal work, under the leadership and guidance of the company's general manager Fan Qi and the vice president of the quality control center Li Shaolin, the company established the ASME code product quality assurance system, and completed the system documents, design documents, and material procurement. And inspection, welding procedure qualification, demonstration product manufacturing, non-destructive testing, etc. During this period, it was inseparable from the careful guidance of the authorized inspector, Mr. Hu Jiaxi, which greatly helped the company's staff in various departments to improve their business level and laid a solid foundation for the company to successfully pass the ASME joint inspection review.

From June 15th to 16th, ASME headquarters dispatched joint inspection team leader Mr. Shao Yong, director authorized inspector Mr. Li Zhijian, and authorized inspector Mr. Hu Jiaxi to conduct a strict review of the establishment and implementation of our company's ASME code product quality assurance system. The operation, marking and recording of relevant elements such as pressure vessel design, process, material, welding, procurement, measurement, non-destructive and material management prepared in accordance with the ASME code were checked, and professional technical recommendations of the ASME code were put forward. Our company immediately suggested that the rectification of each control point should be completed within the first time, and all of them meet the requirements of the standardized products. At the closing meeting, the joint inspection team agreed to recommend to the ASME headquarters that Changzhou Fanqun Drying Equipment Co., Ltd. obtains the ASME "U" stamp authorization certificate.

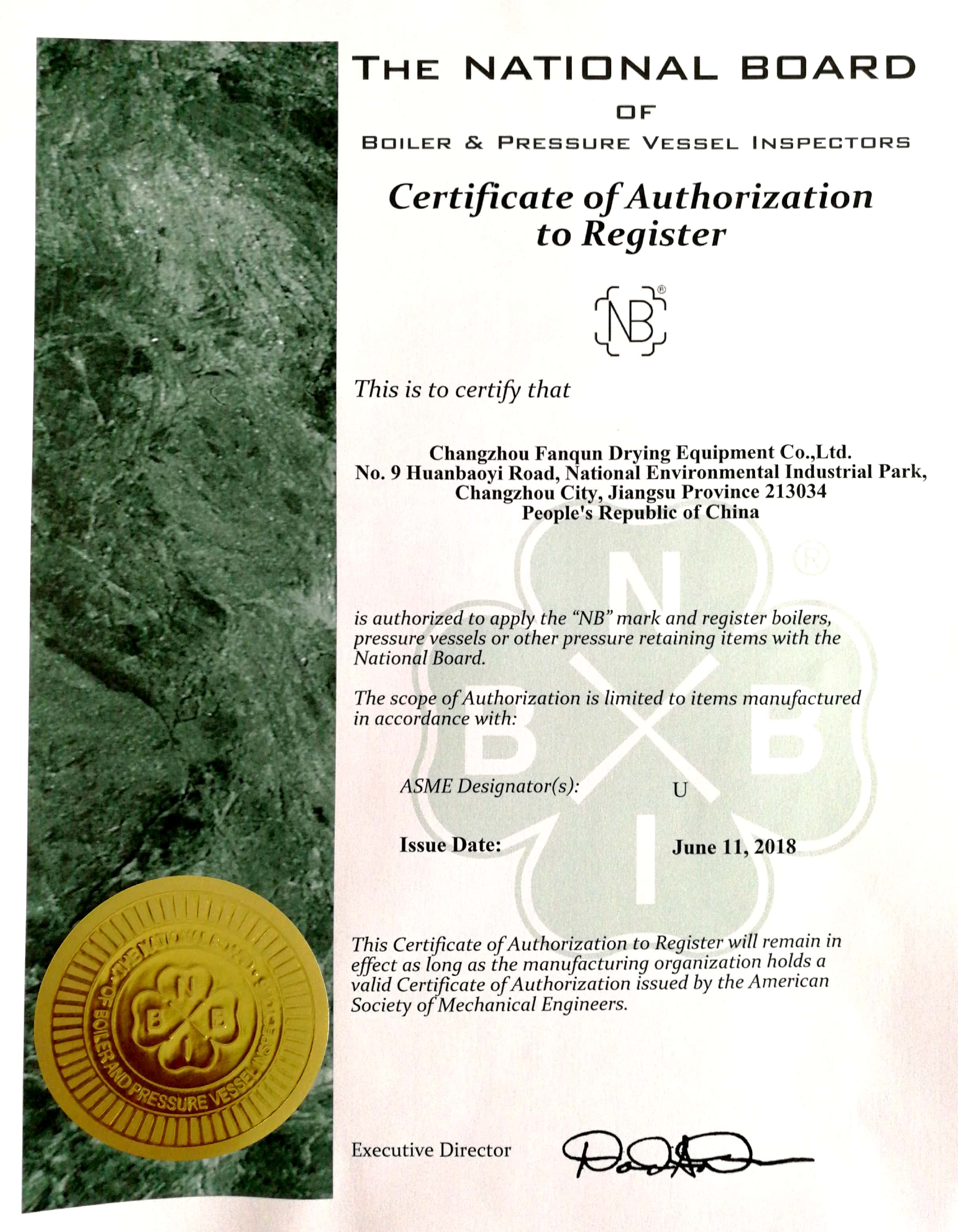

latest version of the ASME "U" stamp certificate.